[flexy_breadcrumb]Ecosed 1200

Fully automatic walk through system and the most compact solution for treatment of industrial process-, rinse- and wastewater.

This system offers the following options and possibilities:

- Detoxify and reduction of Cr6⁺

- Neutralisation

- Flocculation

- Sludge/water separation and dewatering

Working principle

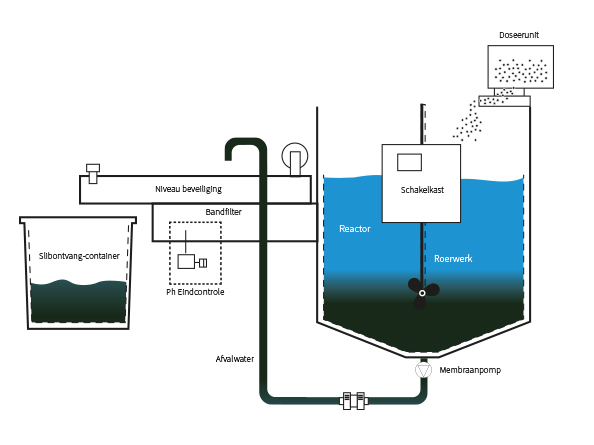

The waste water pump, situated in or beside the waste water storage tank, transfers the water to be treated, to the reactor.

In the reactor, the relevant product, like Ecochrome, Ecostatic, acid or caustic, is dosed.

The stainless steel stirrer started its operation and the reaction takes place.

Within a couple of minutes the chemical reaction is completed and the treated water, together with the built flocs, is continuously transported into the sedimentation tank.

The “clean” water is disposed of by means of the integrated “overflow”, from where it is flowing into the sewer, or it is transferred to a clean water tank for re-use.

The sludge/flocs will sediment in the “Dortmund pipe” and, by means of a double membrane pump, transferred to the belt filter, or chamber filter press, where the definite dewatering takes place.

“Capaciteit 200 – 20.000 liter per badge”

- Fully automatic system

- Very little use of space

- Very low maintenance cost

- Very large capacity

- Very simple operation, by means of a switch box, with PLC

- Available in Stainless steel or polypropylene

- Treating capacity from 1 m³/hour – 22 m³/day

- Oplosmiddelhoudende lakken in combinatie met een spuitcabine (waterwand)

- Watergedragen lakken

- Combinatie van beide systemen

- Metaaloppervlakte behandelingsbaden

- Hout- en meubelindustrie

- Papierfabrieken – drukkerijen